In the machining production, degreased silane process is common, as a metal protection process, has a certain corrosion resistance, oxidation resistance effect, also a process on the metal coating, it has a more important value. However, after the degreasing silanization process of the metal, it will inevitably produce the corresponding waste water, which has a high inorganic salt content and serious pollution, usually contains a small amount of degreasing liquid, silane treatment agent and other cleaning wastewater, the wastewater mainly contains organic matter, suspended matter, a small amount of fluoride and heavy metals, and the sewage is alkaline, causing certain harm to the environment.

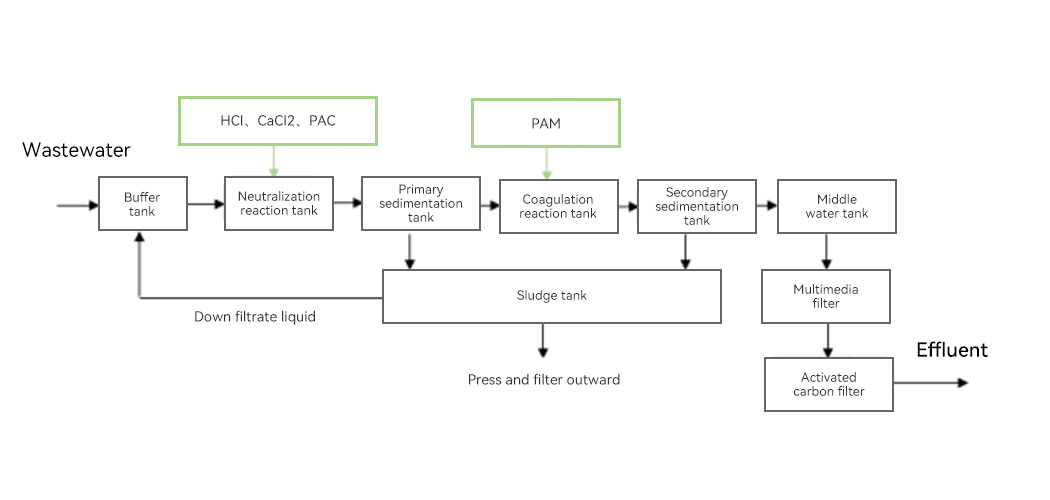

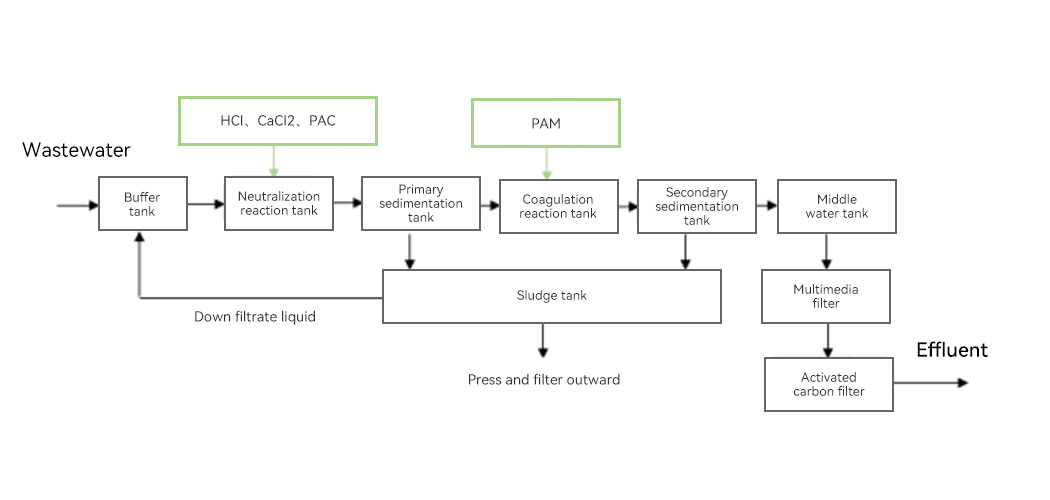

Because the degreased silane wastewater is harmful to the environment and the amount of water is small, a new generation of degreased silane wastewater treatment process is urgently needed to replace the old treatment process in order to meet the requirements of energy saving and environmental protection. Zebang Environmental Protection according to the characteristics of wastewater quality and quantity, launched a new generation of integrated defatted silane wastewater treatment equipment, integrating the skid-mounted device of neutralization, flocculation, precipitation, filtration and other units in one, to achieve the multiple needs of good effluent quality, small footprint, convenient transportation and installation, and simple operation and maintenance.

☆The removal rate of pollutants is high, and the effluent is stable and up to standard.

☆The system runs stably and the operating cost is low.

☆The process produces less sludge and the sludge treatment cost is low.

☆The system has high degree of automation and less operation and maintenance.

☆Integrated mobile, fast and convenient transportation installation.